We provide precision metal components using materials such as SUS, Al, Ti, and invar. These products are produced through a combination of high-precision photomasks and etching, along with technologies such as precision electroforming. The products are utilized as masks for deposition, encoders, electronic component assembly jigs, precision washers, and so on. In addition to thin standalone metal objects, we also provide products subjected to bending, lamination, black plating, and the like.

Metal Laser Processing

In laser processing, a pattern is formed by irradiating a YAG laser onto a metal plate, melting it, and penetrating it. Since a photomask is not required, it is recommended for creating products in small lots. Line width accuracy is ±10um.

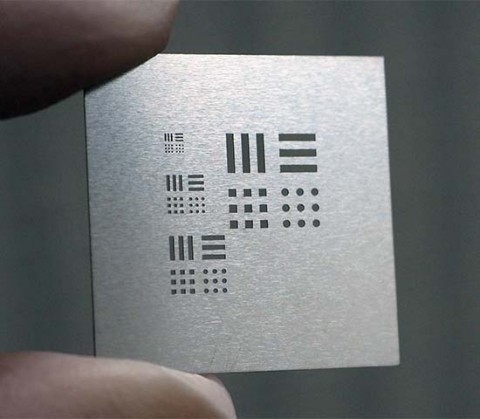

Examples of production by Metal Laser Processing

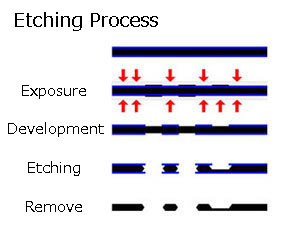

Photo-etching of Metals

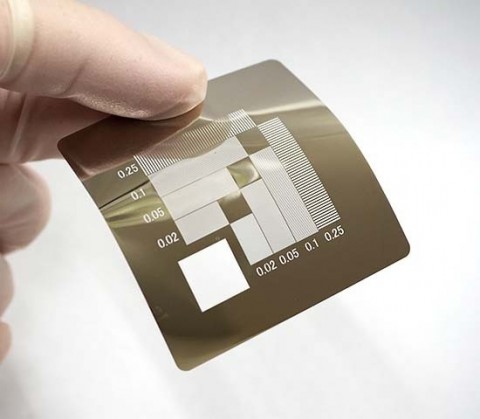

Photo-etching technology is a precision processing technology which, without using a metal mold, is capable of producing complex and minutely detailed shapes with high precision, short lead times, and low cost. We support a variety of metals, including stainless steel, as well as Al, Ti, Cu, and invar. These support half-etching processes as well. We also offer high aspect ratio metallic etching products based on our proprietary methods.

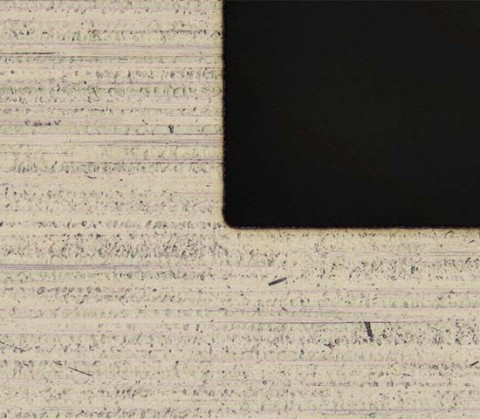

Examples of production using Photo-etching of Metals

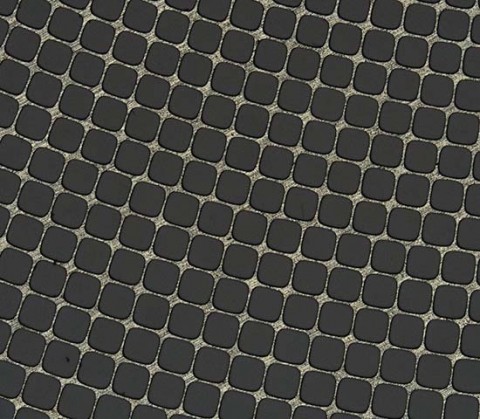

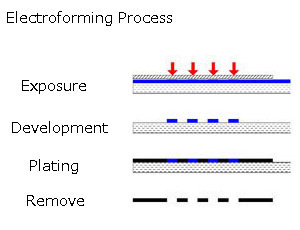

Nickel Electroforming

Shapes that cannot be produced using photo-etching, finely detailed shapes, and the like can be produced to a high degree of precision using nickel electroforming. With electroforming, shapes result from the transfer of a resist image and thus have extremely high processing accuracy.