We provide precision metal components using materials such as SUS, Al, Ti, and Invar. These products are manufactured through a combination of technologies, including laser processing, high-precision photomask and etching, and precision electroforming. Our products are widely used as vapor deposition masks, encoders, electronic component assembly jigs, precision washers, and more. In addition to thin, stand-alone metal parts, we also offer products that have undergone processes such as bending, bonding, black plating, and other treatments.

Metal Laser Processing

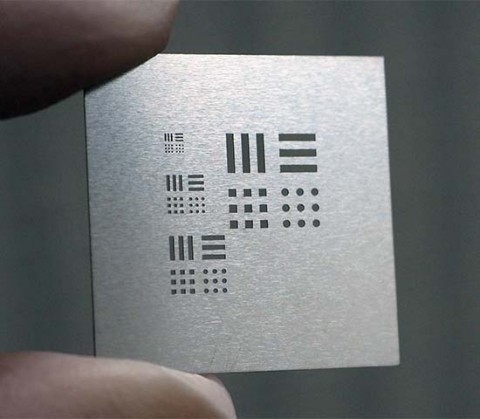

In laser processing, a YAG laser is directed onto a metal plate to melt and penetrate the material, creating patterns. Since no photomasks are required, this method is recommended for small-batch production. The line width accuracy is ±10um.

Examples of Production by Metal Laser Processing

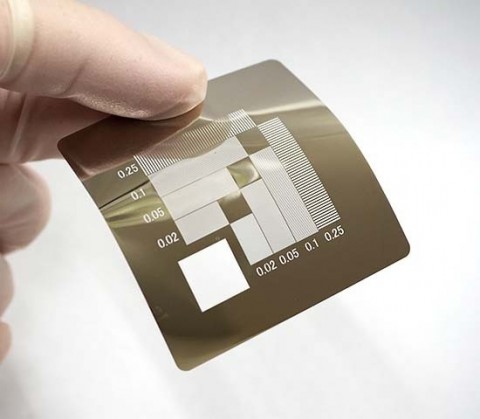

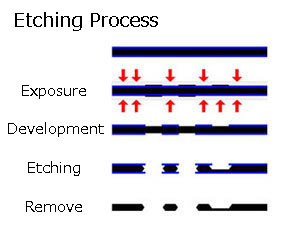

Photo-Etching of Metals

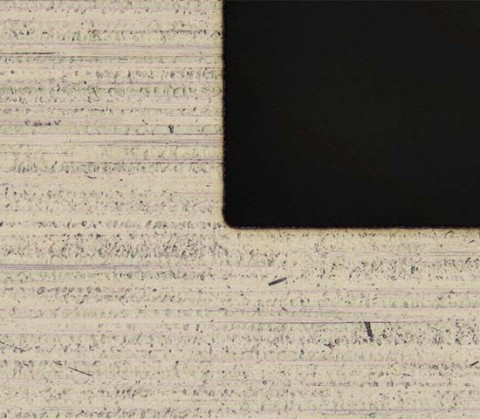

Photo-etching technology is a precision manufacturing process that enables the production of complex and fine shapes with high accuracy, short lead times, and low costs, without the use of molds. It is compatible with a variety of metals, including SUS, Al, Ti, Cu, and Invar. These metals can also be processed using half-etching. Additionally, we provide metal products with high aspect ratios using our unique techniques.

Examples of Production by Photo-Etching of Metals

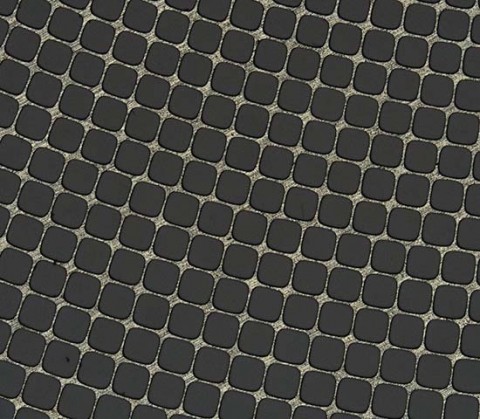

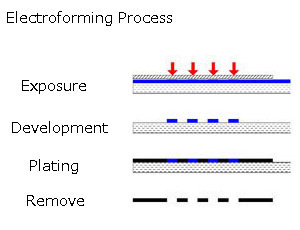

Nickel Electroforming

Nickel electroforming technology allows for the precise manufacturing of shapes and fine details that are impossible to produce with photo-etching. In electroforming, the shape is transferred from the resist pattern, enabling extremely high processing precision.