We offer optimal guidance related to quality, cost, and delivery.

There are two types of photomasks: glass masks and film masks. In addition, there are two types of glass masks: chrome masks and emulsion masks.

Chrome masks are masks for which patterning is performed on a glass substrate onto which chrome and chrome oxide have been sputtered.

Emulsion masks and film masks are masks for which patterning is respectively performed on a glass substrate or PET coated with a photographic silver halide emulsion.

At EQUA, we provide chrome masks and film masks.

Types of Substrates

The substrate material used for photomasks is either soda lime (SL) or synthetic quartz (Qz) for glass substrates, or PET for film.

Glass Substrates

The major differences between soda lime and synthetic quartz are the thermal expansion rate and the transmittance rate. The thermal expansion coefficients and transmittance rates are as follows.

| Types | Thermal Expansion Rate | Transmittance Rate |

| Synthetic Quartz | 0.5 x 1 0-6 ( 0.05 um / ℃ / 100 mm ) | 90% / 200 nm and over |

| Soda lime | 8.0 x 10-6 ( 0.8 um / ℃ / 100 mm ) | 83% / 380 nm and over |

Film Substrates

Films expand and contract due to the effects of not only heat but also humidity.

| Types | Thermal Expansion Rate | Humidity Expansion Rate | Transmittance Rate |

| PET | 18 x 10-6 | 11 x 10-6 | 90% / 200 nm and over |

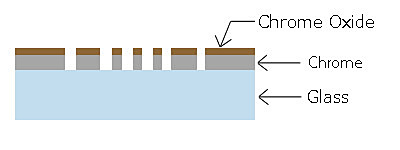

Chrome Films

The chrome thin film on glass substrates has a double-layered structure, with the first layer being pure chrome, and the second layer being chrome oxide. The respective thicknesses of these layers are approximately 700 Å and 300 Å, for a total of 1,000 Å.

The chrome oxide is affixed for anti-reflection purposes, and exhibits a brown color. The presence or absence of these chrome films in particular areas on the glass substrate is determined in the photo-etching process, and a pattern thus results.

Chrome Film Types and Structure

■Chrome Masks

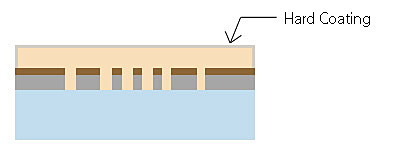

■Chrome Masks with a Hard Coating

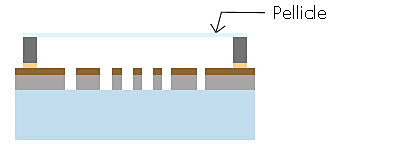

■ Chrome Masks with Pellicles

A Pellicle such as that in the diagram to the left is laid down on the surface of the chrome mask in order to protect it from adhesion by particles and other substances. In particular, this is used in exposure machines such as steppers; the type of pellicle used varies depending on the type of exposure machine.

Silver Halide for Film Masks

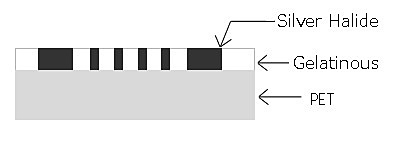

With film masks, the pattern is formed as a result of the fact that the silver halide in the emulsion layer coated onto the polyester substrate changes to black silver-metal when subjected to development processing.

Since the surface is gelatinous, it is delicate and prone to scratching, but these are more modestly priced than glass masks.