At Equa, we process glass using various techniques such as glass etching, machining, and sandblasting, and we will guide you to the most suitable processing plan according to your desired accuracy, purpose, and budget. We also create glass products with patterns such as chrome and measure product shapes. We can create custom storage cases for specially shaped glass products as well.

Glass Etching

We offer glass etched products using photo-etching technology, providing high-precision shapes for microchannels, spacer applications, and the like. There are two types of glass etching: dry etching and wet etching.

Examples of production using Glass Etching

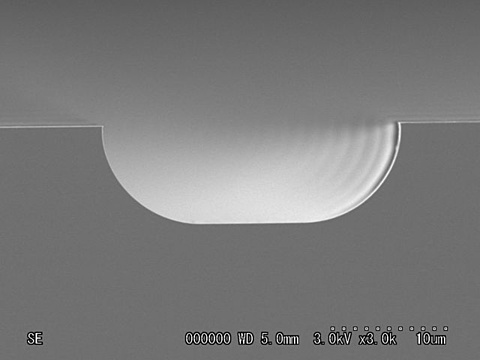

This is a cross-sectional view of groove processing by glass etching. The width and depth of the groove can be precisely controlled.

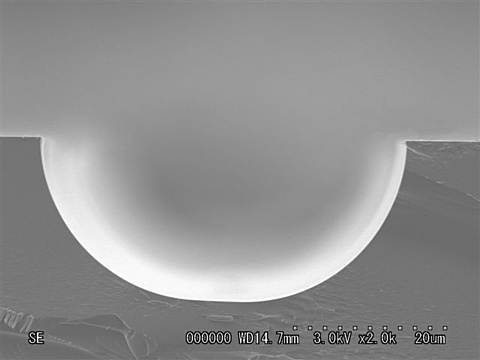

Glass etching also allows processing of convex and concave forms with a flat bottom.

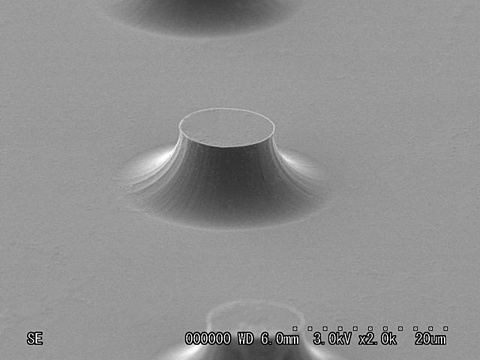

Sandblasting

This is a technology that creates a specified shape by blowing a special sand material onto the glass substrate. We can process counter borings, through holes, etc., as well as process different patterns on the front and back sides. It is sometimes used to process glossy glass surfaces to make them light-diffusing.

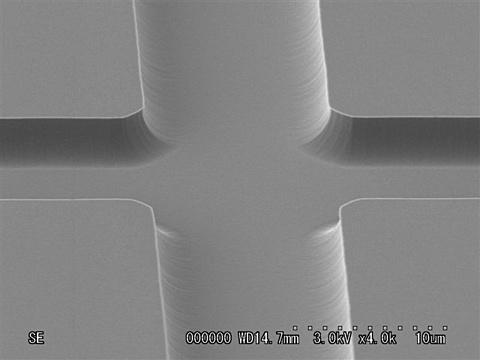

Precision Cutting using a Dicing Saw

We use a dicing saw to cut glass substrates into desired sizes with high accuracy. The machining shape can be rectangular, circular, or a combination of these. It is also possible to process glass substrates patterned by photo-etching.

Machining Processing

We can handle following processing: High-precision machining of extremely special external shapes, micro-drilling of various types of glass, and deep hole machining with high aspect ratios.